In modern lighting design, LED light strips have become a "universal artifact" for residential and commercial lighting due to their high flexibility, energy saving and visual effects. The most common voltage options for LED light strips are 12 volts and 24 volts. You may have questions, what is the difference between 12VDC light strips and 24VDC light strips? Which one should I choose? This article will give you a better understanding of them and help you choose the light strip that suits your project.

1. The following table makes a simple comparison:

Table comparison:

| Comparison dimensions |

12V LED light strip |

24V LED light strip |

| Brightness performance | Suitable for atmosphere lighting, ordinary home Brighter | suitable for large projects and commercial use |

| Max run length | Recommended < 5 m | Up to 10 m or longer |

| Voltage drop control | Obvious, need to pay attention to the power supply plan | Small voltage drop, more stable |

| Installation complexity | Simple, can use a smaller and more compact power supply | Slightly higher, larger power supply |

| Initial budget | Low, suitable for entry-level users | Slightly higher, but more economical in the long run |

| Strong compatibility | Ideal for many low-voltage systems | More requirements for projects |

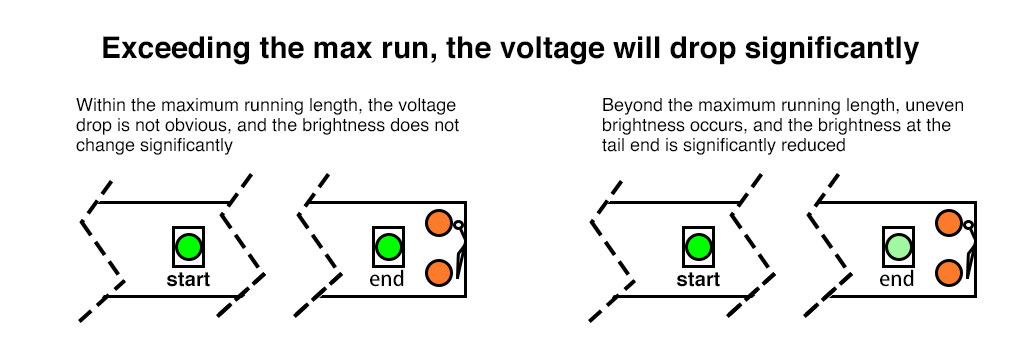

2. Issue on the maximum running length of the light strip:

(1) 12 volt light strip: The maximum running length of a 12 volt LED light strip is about 5 meters. If it exceeds this length, it is easy to have uneven brightness and significantly reduced brightness at the end. Thicker wires or additional power supplies are required to maintain the brightness of the light strip.

(2) 24V light strip: The maximum running length of a 24V LED light strip is about 10 meters, and there is generally no significant voltage drop within this length. Therefore, 24V LED light strips are more suitable for large-scale project installations or commercial space lighting.

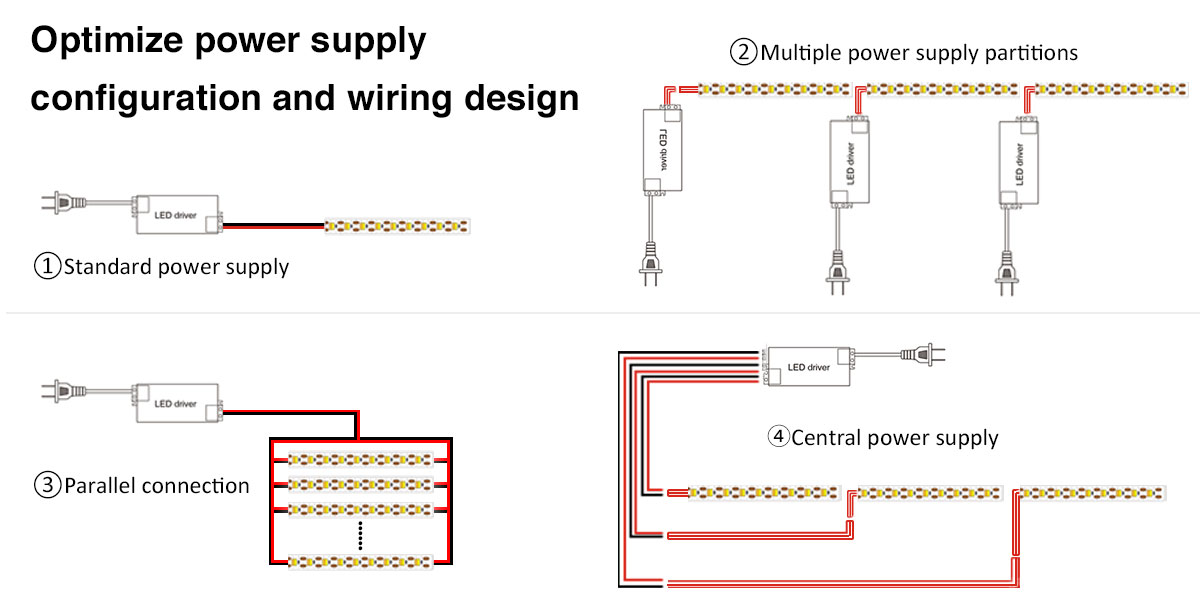

3. How to solve the voltage drop problem?

To ensure that the LED light strip system operates efficiently and stably and minimize the light decay problem caused by voltage loss, the following strategies can be adopted:

(1) Ensure that a high-quality power supply that matches the voltage, current and total power of the light strip is used. For example, a 12V LED light strip requires a 12V power supply, while a 24V light strip requires a 24V power supply. Avoiding voltage mismatch may cause damage to components or poor performance.

(2) Optimize power supply configuration and wiring design. For systems that require longer line operation, use parallel connection, central power supply, dual-end power supply, or use multiple power supply partitions to maintain consistent light strip brightness.

(3) For long-distance continuous lighting or high brightness requirements, it is recommended to use LED light strips with higher input voltage to avoid voltage drop problems. For example, use 48V, 36V and 24V instead of 12V and 5V.

(4)Choose high-quality light strips with thick copper PCB to effectively reduce line resistance. The thicker the copper wire, the stronger the conductivity. The more current flows through, and the more stable the circuit.

In summary, the advantages of 24VDC LED light strips far exceed 12VDC LED light strips. If possible, especially in large lighting projects, it is recommended to use 24VDC LED light strips. Are you still looking for the perfect LED light strip for your project? Please explore our 12V and 24V LED COB flexible light strip product range.

Post time: Jul-09-2025